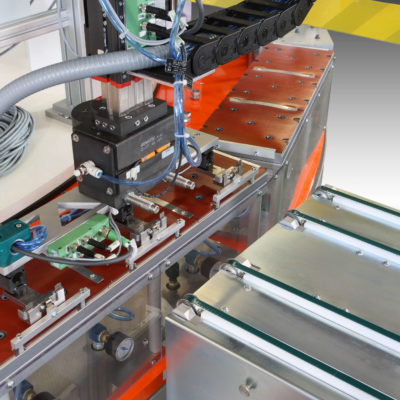

This is followed by three printing stations, where the surface of one of the three wafers is printed with aluminium paste. The rate at which the wafers break during the pad printing process is considerably reduced compared to the sheet printing process, due to the relatively even distribution of surface pressure during printing. The freely programmable servo motor allows for optimum paste absorption and transfer times, with high outputs at high cycle rates. The surface of the prints and the position on the wafers are then checked by an image processing system. Bad parts are removed, good parts are transferred to a conveyor belt which takes them to a kiln for further processing. The system works in a 24h three-shift operation, printing approx. 2500 pieces/h.

Aluminium printing

Compared to the sheet printing process, the pad printing system offers a noticeably lower rate of breakages of delicate wafers in high cycle rates. Additional advantages include greater availability of systems due to shorter cleaning times and reduced consumables costs due to longer-lasting pads and clichés.