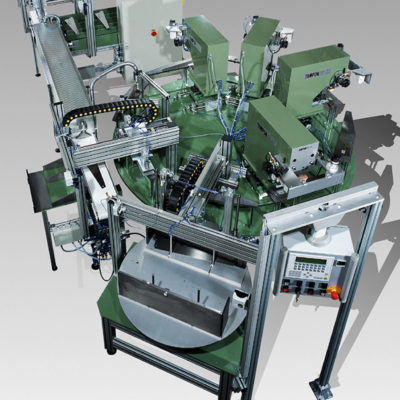

Pad printing machines for printing wood saw blades

A tooling industry solution

One of the world’s largest manufacturers of hand tools also produces wood saw blades. Until now, the saw blades have been provided with appropriately labelled secondary packaging to supply the product information. A solution is sought for labelling the saw blades directly in order to save on this packaging while also meeting product liability requirements. The products to be labelled will be of various sizes, from 7 mm x 300 mm to 140 mm x 720 mm, weighing up to 1.2 kg. The saw blades are to be printed with a two-colour logo and a black bar code on a white background.