TC In-mould printing system

TAMPONCOLOR® TC In-mould Printer

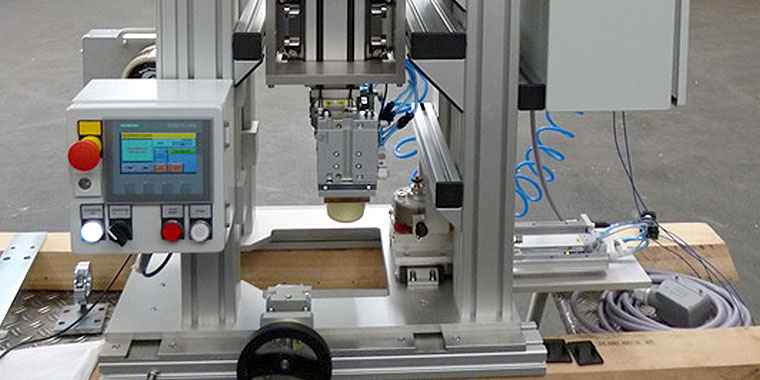

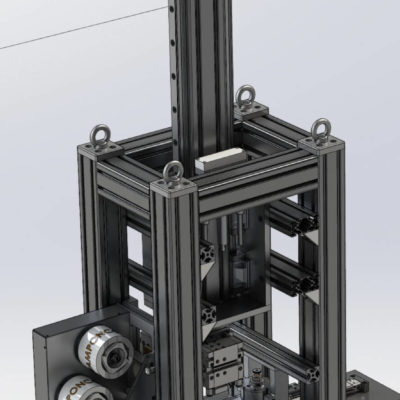

The TAMPONCOLOR® In-mould Printer has been developed in cooperation with Chemnitz University of Technology (Plastics Institute) to decorate plastic parts during the injection moulding process.

This innovative, modular pad printing system can be assembled directly onto a injection moulding machine and communicates entirely via the existing EURO-MAP interface.

It can be easily dismantled and removed for accessibility to the tool area during set-up.