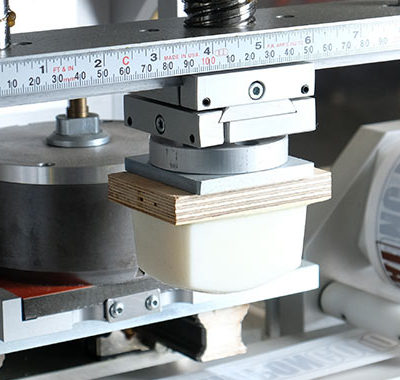

Servo-electrical pad printing machines

Servo-electrical pad printing machines are used for printing, inscribing, labelling and decorating products in single or multiple colours with a high degree of accuracy and colour saturation. Freely programmable speed allows for exceptionally high-quality printing. It is possible to perform more-colour-printing with one machine by using an additional NC-axis or a handling system for printed items.